Build Trays

FAQ

Build Trays

Estimated print time is longer than normal

Suction cup

Most build trays have perfect films with no damages or scratches.

Certain geometries can cause more wear & tear to the film requiring some extra care.

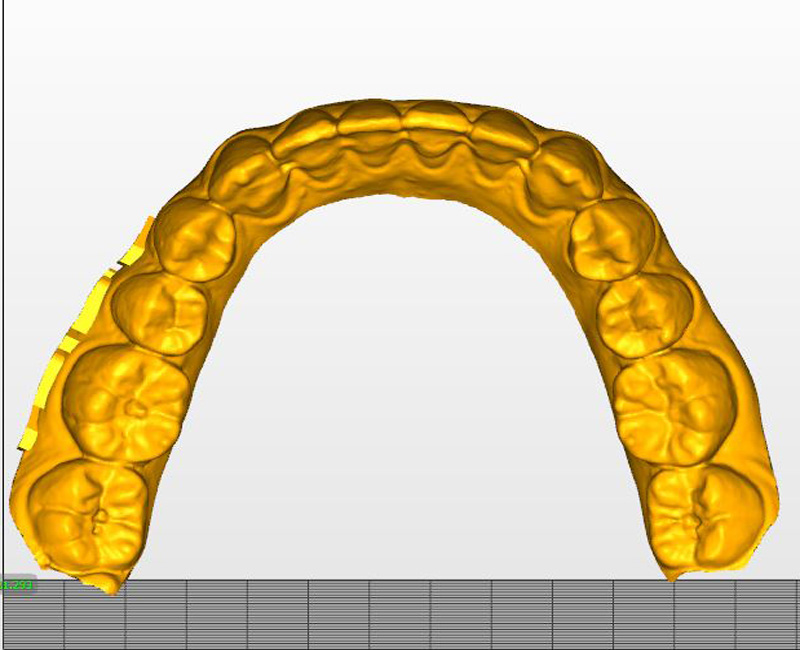

Suction cup refers to hollow cavities in a model.

These cavities trap resin during the printing process and cause print failures or damage to the build tray.

Preventing Suction Cup

There’s a few ways to prevent trapped volume/suction cup.

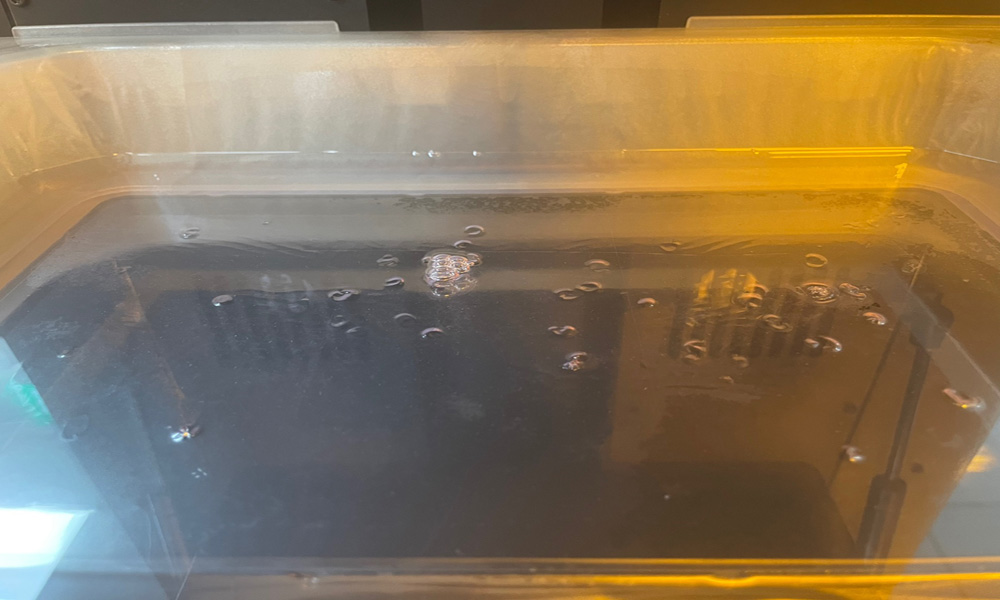

The first and easiest is always ensure your build tray is filled at least 75% before commencing a print to prevent air being pushed down. This will not only be a potential cause for print defects, but also significantly increase printing times.

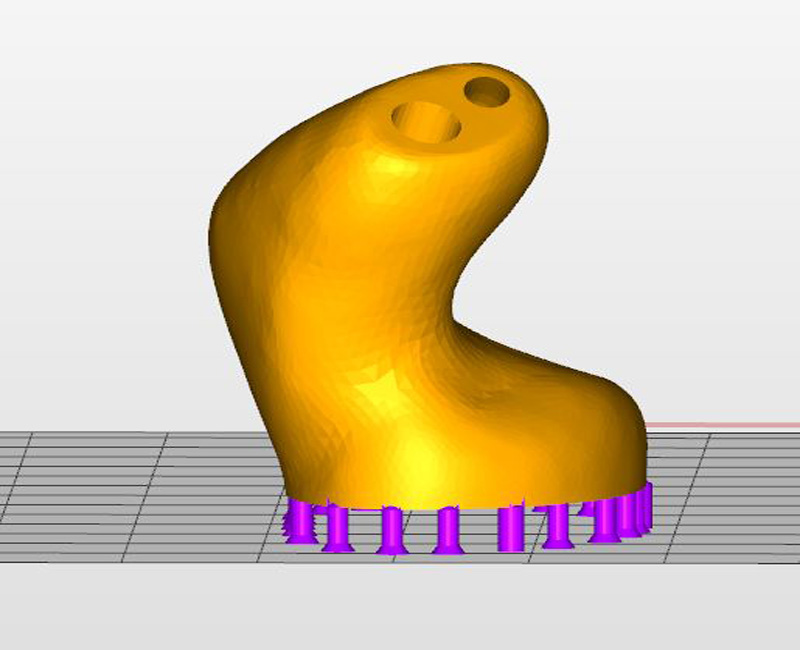

Hollow parts

If your model is hollow, it will create trapped volume.

Placing drain holes at the base of the model will allow resin/air to escape.

Adding supports to hollow models will also prevent trapped volume/suction cup.

Always print with a baseplate when adding supports.

Orientating the parts on a different angle may prevent suction cup completely.

If you are still experiencing technical difficulties

please launch a support ticket via the button below.

If none of these tips worked, please launch a support ticket here >