PRO 4K XL

Printer safety & manuals

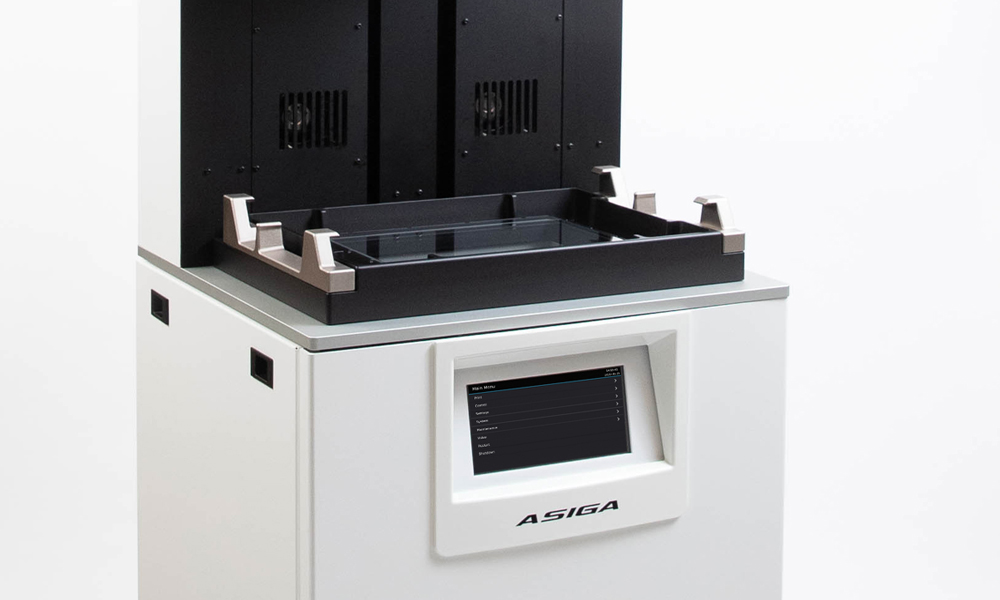

Printer Overview

The diagram below illustrates the main components of your PRO 4K XL

Bodywork

Below is a summary of the main Components on the PRO 4K XL.

Hood

The PRO 4K XL Hood is constructed of UV blocking hard plastic. This protects the resin from being cured by natural light & the user from UV light emitted.

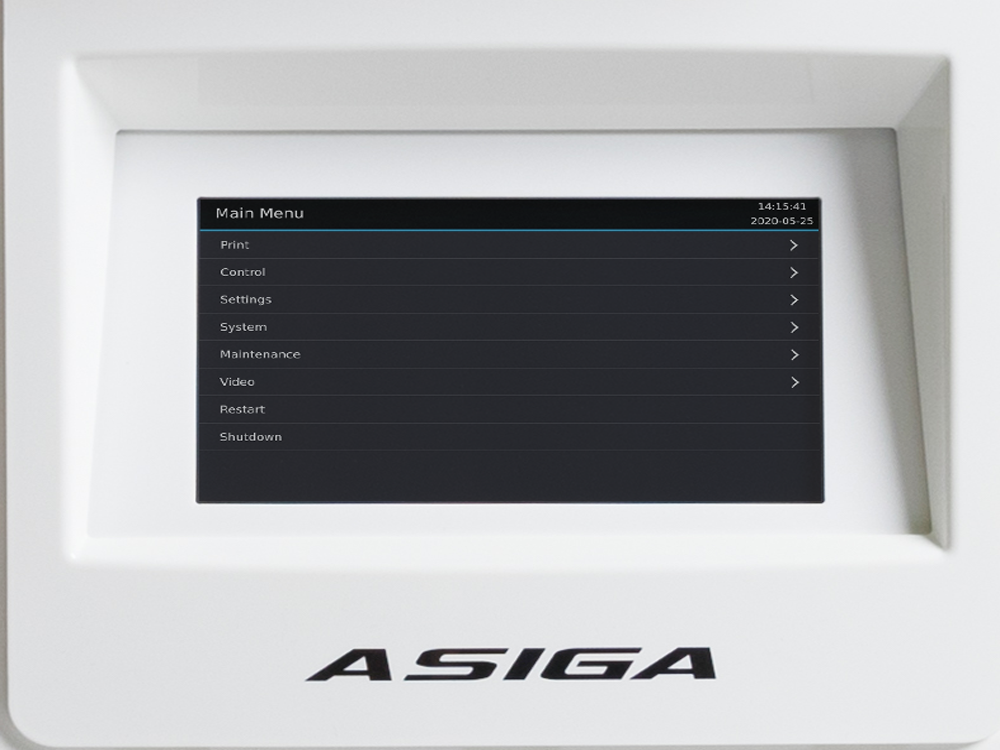

Front Panel

The front panel is the white surround that contains the LCD screen. The LCD screen is the main control panel for the printer.

Rear Covers

The top cover is constructed of white aluminium and a crisp black plastic fan cover that houses the connectivity ports.

Power/Network connection panel & Optional Gas Inlets.

- Ethernet port

- Printer serial

- Power switch

- Power connector

- Quick release gas inlet/outlet

Side panels

The side panels are constructed of metal and painted white.

These can be removed by disengaging the black plastic clips and hinge open.

Wheels

The PRO 4K XL comes with four wheels. Two leader wheels that lock in place and two followers.

Under the hood

Build Platform Holder

The build platform holder is the arm that protrudes from the vertical stage. The build platform calibration screw is located here.

Build Platform

The build platform is the centerpiece of the PRO 4K XL. It is engineered from anodised steel which makes it extremely durable.

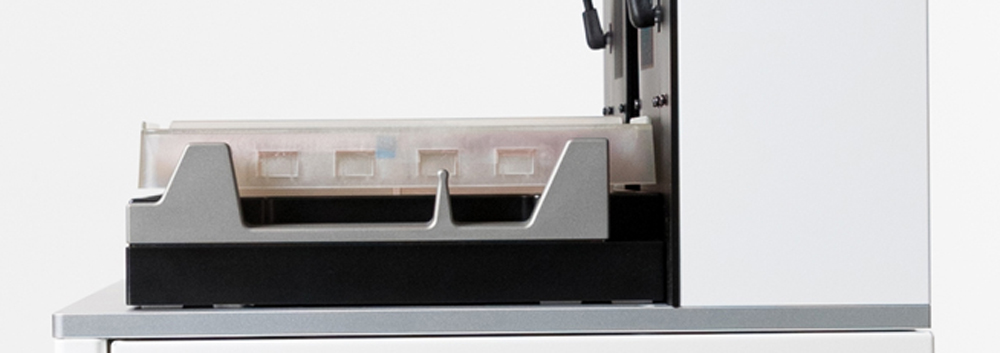

Basin

The basin holds the resin tray and acts as a gateway between the resin and UV light. This glass plate must be kept crystal clean and free from debris.

Build Tray Sliders

Anodised steel sliders to hold the build tray in place during printing.

Build Tray

Build trays contain the resin during the printing process. They are constructed of a flexible film within a rigid plastic frame. Asiga recommends one Build Tray per material. Do not use the same Build Tray for multiple materials as this may create material cross-contamination and transfer of uncured materials.

Asiga SPS™ technology

Asiga SPS™ technology is managed by 4 position encoders that surround the basin glass. These sensors detect actual build platform positioning to ensure the layers in your 3D printed part are formed accurately.