MAX

Printing on the MAX

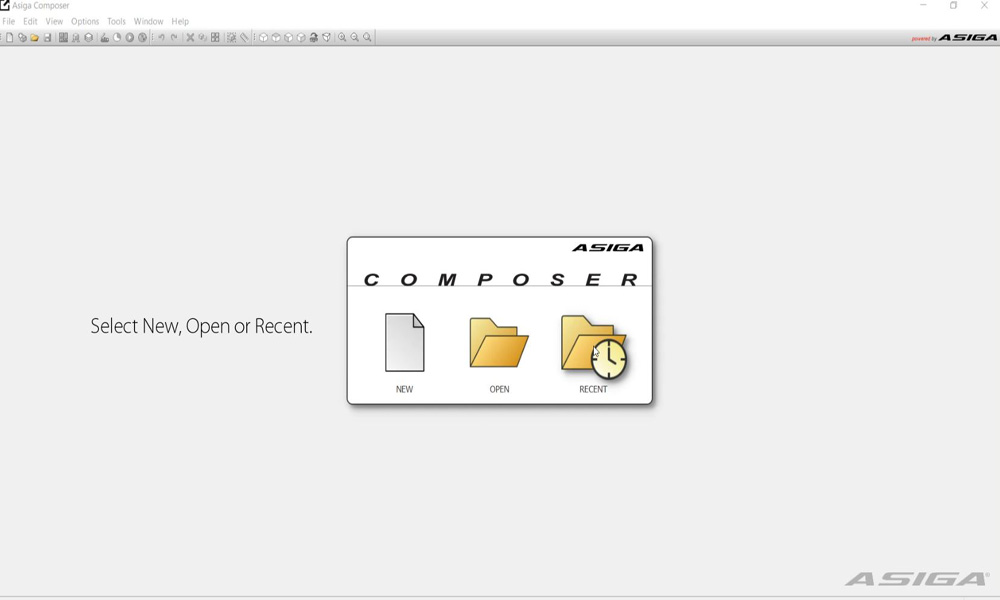

Install Composer

Composer is the bridge between design software & Asiga 3D printers.

Use Composer to prepare parts for 3D printing including nesting, scaling, positioning, supporting & more.

Composer is compatible with a range of file formats including:

- STL

- SLC

- PLY

- STM

System requirements

Operating System

Windows

Mac

Linux

Windows

Mac

Linux

Processer:

1.6 GHz multi-core

Memory:

2 GB

Graphics:

64 MB, OpenGL 2.0 or later

Mouse:

3 button with scroll wheel / trackpad

Setting up your first print in Composer

Watch the below video to learn about starting a new print in Composer.

Before starting a new print ensure you have correctly set up your printer.

It is essential that your printer is correctly set up before starting a print to avoid failures.

Access printer via web interface

The printer’s web interface allows you to interact with the printer from the comfort of your desk.

Stirring material

A crucial step in starting a print is ensuring the material is stirred.

Pigments in resin will settle over time making this such an important step.

Starting a print

When a build has been submitted to the printer, follow the steps below to start a print.

To start a print from the web interface click here >

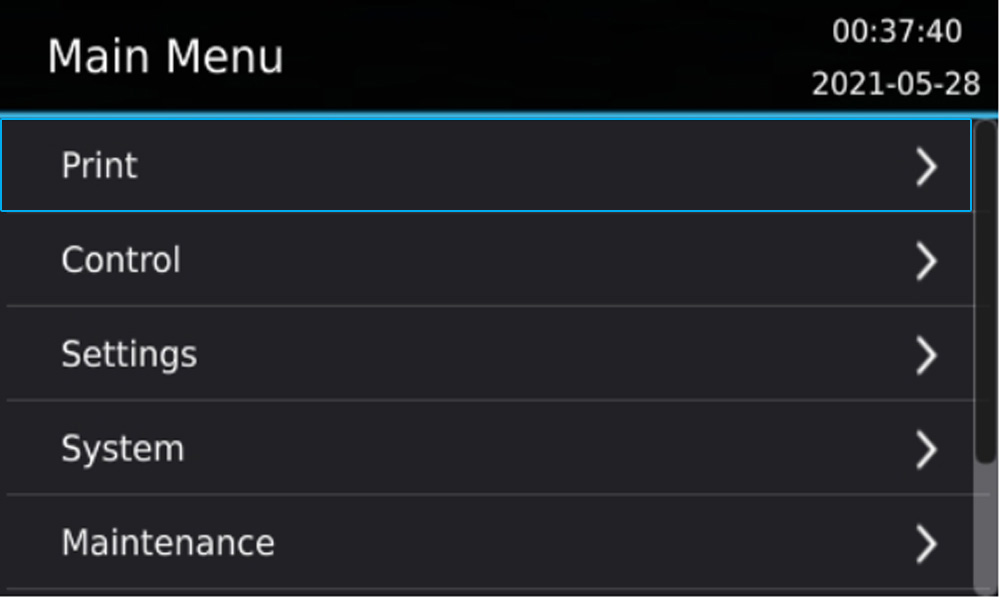

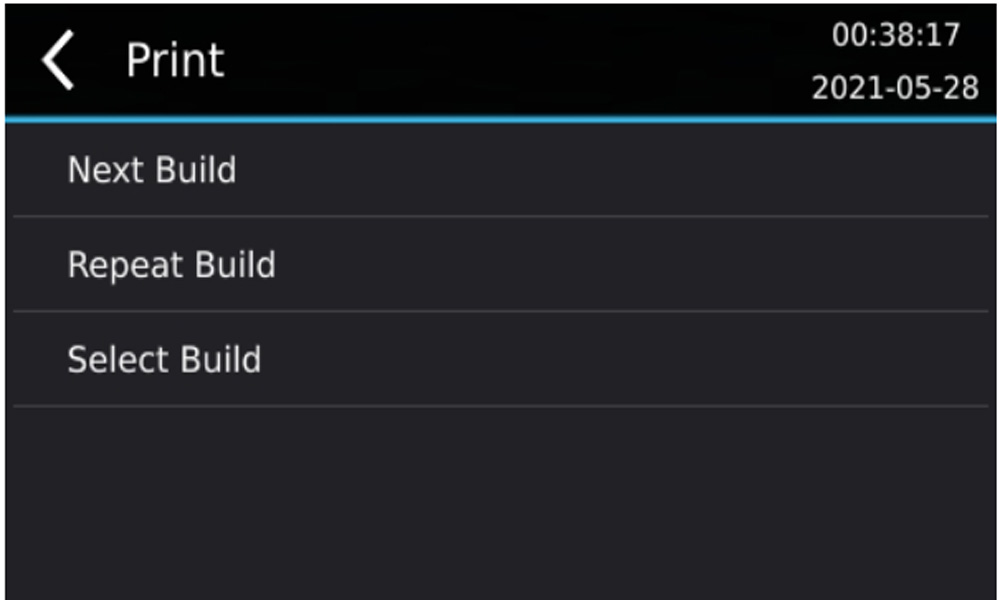

On the printer Main Menu

- Select Print

Select one of the following options:

- Next Build:

lists the next build in the print queue. - Repeat Build:

Allows you to repeat the previous print. - Select Build:

Select from a list of all builds in the print queue.

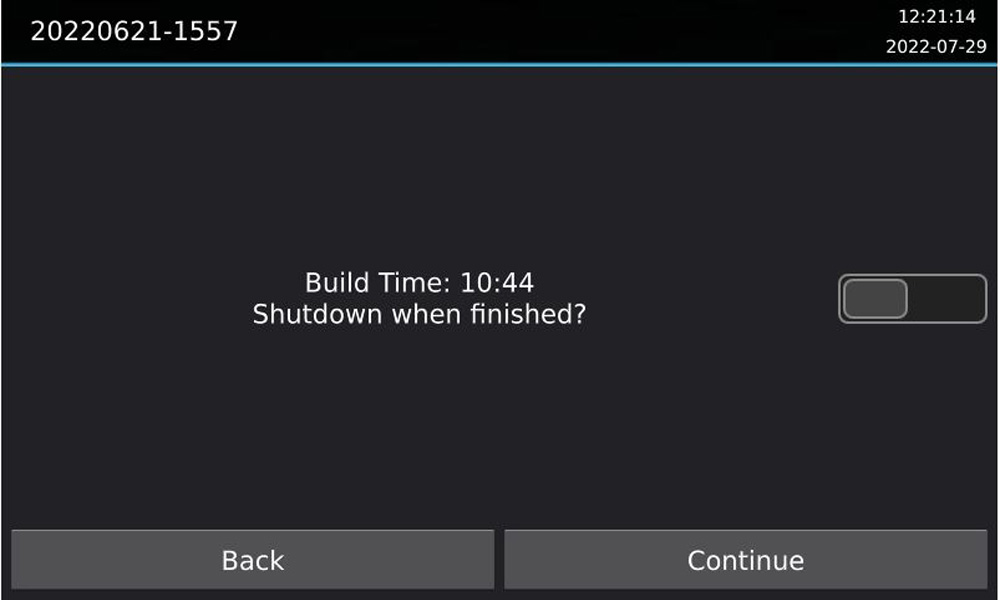

Auto shutdown is an option that will turn the printer off when the print is finished.

Select Continue.

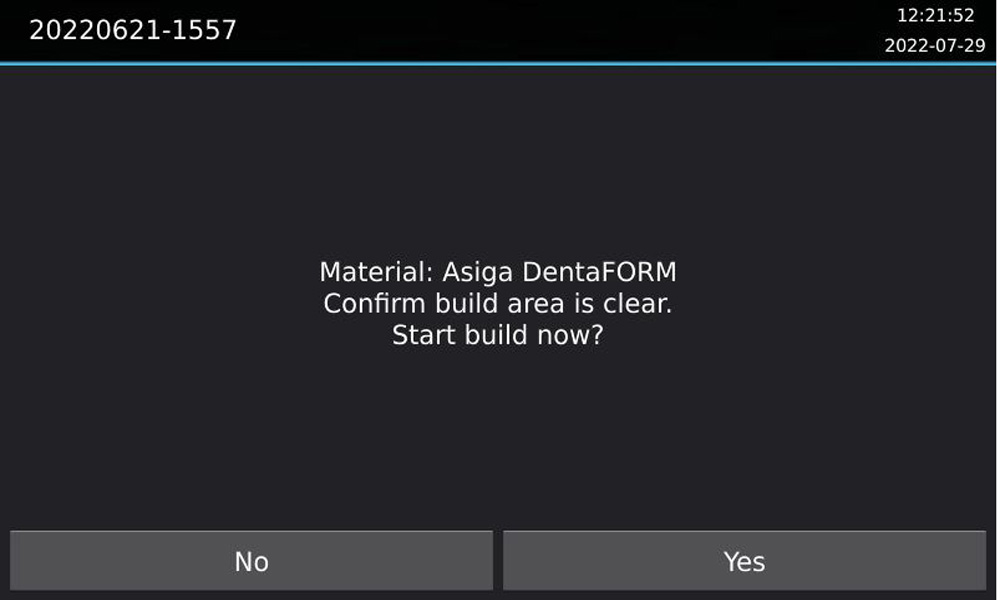

Confirm that your tray is filled with the correct material and select Yes.

Removing a build

When the printer has finished a build, you can now start to post-process the parts.

Click here to learn more about removing parts & post processing.